Product introduction

Environmental noise reduction project

Technical Parameters

The noise of a diesel generator set can reach 110 decibels or more within one meter. It becomes an environmental problem that we must face. According to the working principle of a diesel generator set, its noise generation is very complicated. The noise of diesel generator set includes several parts: smoke exhaust noise, mechanical noise, combustion noise, cooling fan, exhaust noise, inlet noise, generator noise.

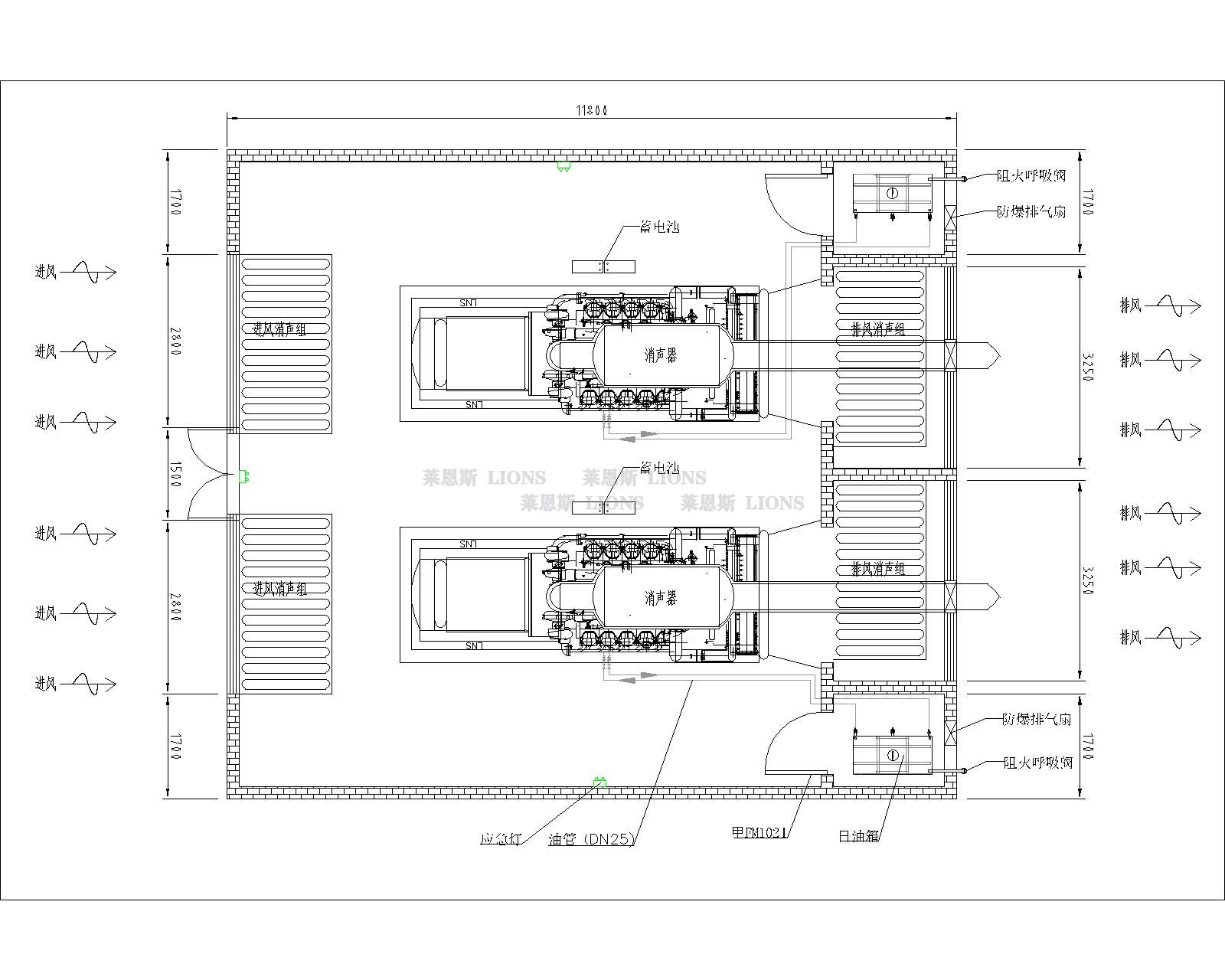

Noise reduction processing in generator room generally requires sufficient space in the engine room, because diesel generators are a type of equipment that requires smooth ventilation to ensure that the engine needs sufficient air supply and normal generators to have good heat dissipation conditions. Otherwise, the unit cannot guarantee its normal performance.

The noise reduction of the generator room has been carefully designed to make scientific and reasonable noise reduction treatment for the generator set. Adopting special process design, perfect and reasonable diversion design of air intake and exhaust system processing, and advanced sound insulation and sound absorption materials, made by the unit to absorb and isolate the noise of the unit, through noise reduction processing, the noise of the machine room can reach User requirements

The environmental protection and noise reduction of the generator room is a non-standard customized project according to the customer's site conditions. The structure size varies according to the engine brand model and power. The specific detailed plan depends on the site conditions and customer requirements.